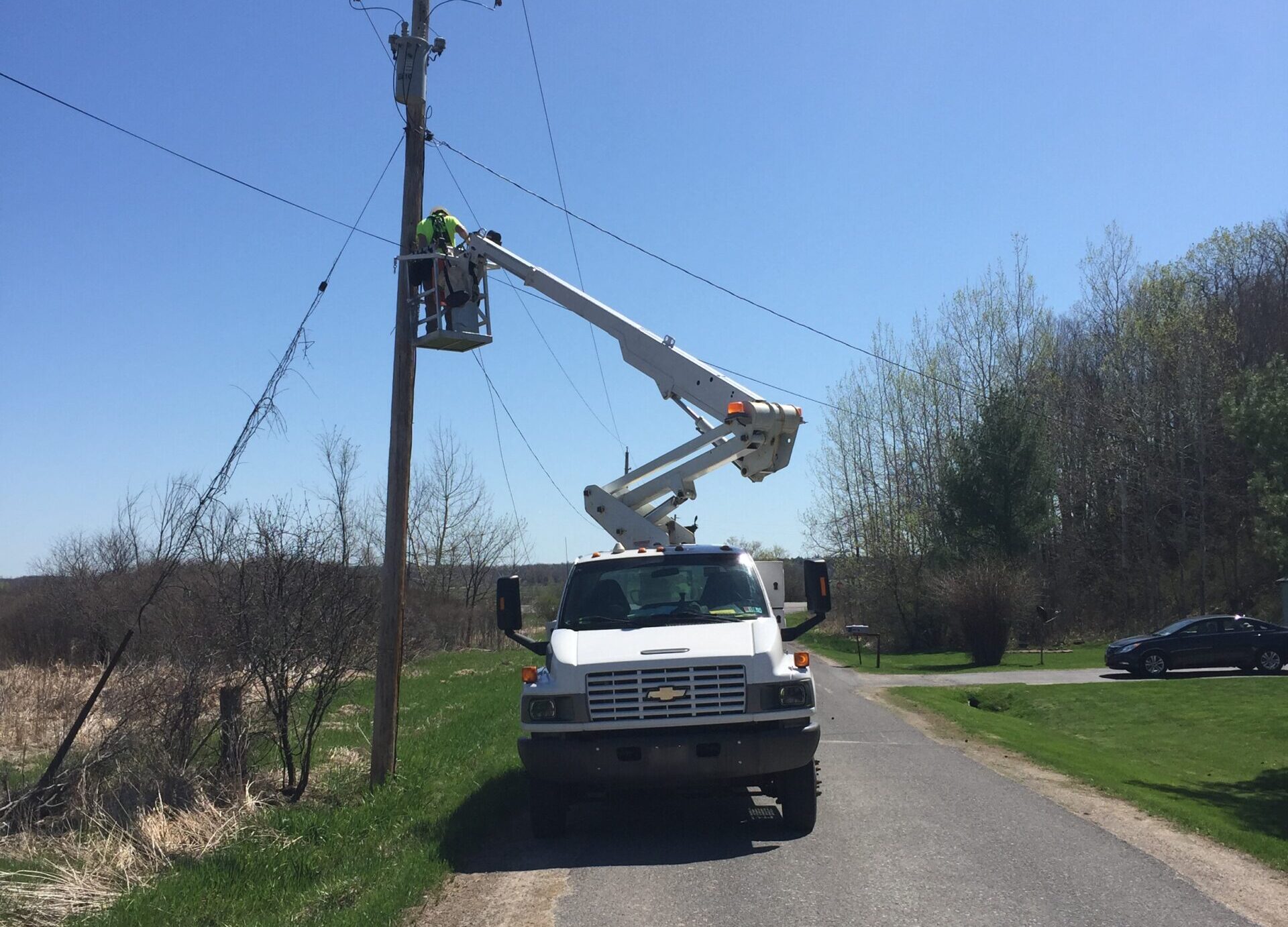

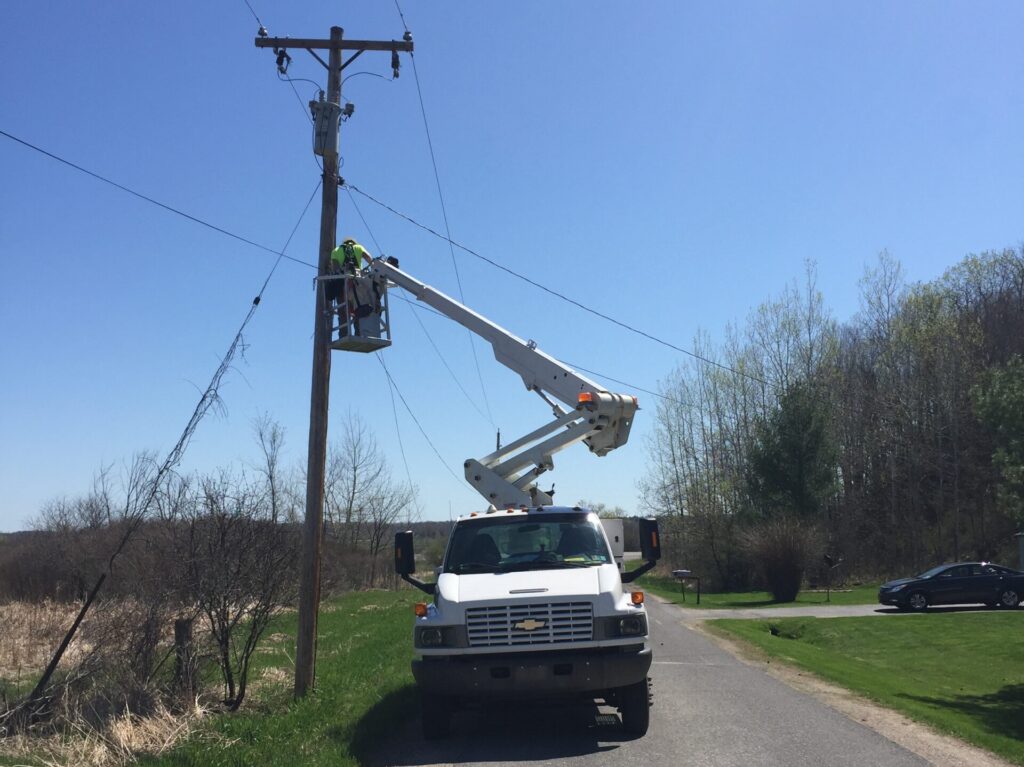

Whether you’re passing strand across a remote utility pole or splicing fiber with precision on a tight timeline, having the right tools is non-negotiable. For aerial fiber linemen, every install depends on a mix of hands-on tools and field-tested technology that enable safety, speed, and signal integrity.

At TermLink Solutions, we equip our aerial fiber linemen with best-in-class gear—and train them to use it with confidence. Here’s a look at what lives behind the bucket.

The Role of Tools in Every Successful Aerial Fiber Job

The right tools don’t just improve efficiency—they protect crews and ensure long-term reliability.

When a aerial fiber lineman’s tools are:

- Calibrated

- Properly maintained

- Familiar and repeatable

…it means:

- Fewer errors

- Faster installs

- Safer job sites

- Fewer callbacks

10 Must-Have Aerial Fiber Lineman Tools on Every Job

Here’s what you’ll find in every TermLink truck, trailer, and toolbelt:

1. Hydraulic Reel Trailer

Controls fiber tension during pulls and protects cable from microbending or crush damage.

2. Lasher Head & Cable Blocks

Used to secure fiber cable to messenger wire along spans. Our crews use heavy-duty lashing gear with adjustable tension settings.

3. Impact Wrench with Torque Limiter

Essential for securing bolts on pole hardware without over-tightening. Safety and consistency are key.

4. Fusion Splicer & Fiber Cleaver

The core of clean, low-loss splicing. We use precision cleavers and splicers that meet exact splice-loss specs for our clients.

5. OTDR & Power Meter

These tools confirm signal strength, test splice integrity, and document readings for handoff or audits.

6. Fall-Arrest Harness & Safety Gear

OSHA-compliant gear including ANSI-rated harnesses, lanyards, and carabiners to keep linemen protected at elevation.

7. Voltage Detector & Hot Stick

Fiber linemen often work near live plant. Proper voltage detection keeps crews safe when power infrastructure shares poles.

8. Class E Hard Hat & Arc-Rated Gloves

PPE is a must in all weather. We require gloves and headgear that meet the latest ANSI and FR requirements.

9. GIS-Enabled Tablet or Mobile Device

Used for route mapping, daily reporting, redlining as-builts, and uploading photos or OTDR readings in real time.

10. Splicing Tent & Portable Power

For longer runs or overnight jobs, we bring splicing tents and portable power sources to ensure speed and environmental control.

Tools Are Just the Beginning—Training Is What Sets Us Apart

At TermLink, every crew member:

- Completes 40+ hours of gear-specific training annually

- Is tested on OTDR reporting, splicing quality, and climbing safety

- Works in small, consistent teams to build repeatable processes

We don’t just hand out tools—we teach our crews how to use them with the precision that clients expect and inspectors require.

What’s New: Fiber Tool Tech Trends in 2025

We’re constantly watching the market for tools that improve job speed and data accuracy. A few innovations we’re watching this year:

- Battery-powered mini-lashers for mid-span install speed

- Drone-assisted span inspections

- Smart-glasses with augmented overlay for redlining and maps

- Low-noise fiber blowers for in-building conduit drops

Why This Matters for Your Next Project

When you’re hiring a fiber contractor, the tools in the truck matter more than you think. Outdated or missing equipment causes:

- Delays in install timelines

- Lower splice test results

- Increased safety risks

- Costly rework down the line

At TermLink, we keep our trucks stocked, our crews trained, and our fiber installs efficient—because you deserve a partner that’s as ready as you are.

Ready to Work With a Crew That’s Fully Equipped?

Let’s build your next aerial fiber project the right way—from the tools up.

Contact TermLink Solutions today to get started.