Every fiber optic network depends on one thing: a clean, seamless signal from point A to point B. That signal strength, and the reliability that comes with it, starts with fiber splicing.

At TermLink Solutions, fiber splicing is one of the most important steps in our installation process. In this post, we’re breaking down what fiber splicing is, how it works, and why it plays such a critical role in network performance.

What Is Fiber Splicing?

Fiber splicing is the process of joining two fiber optic cables together to ensure uninterrupted light transmission. It’s required when:

- Extending existing fiber lines

- Repairing damaged cables

- Connecting new segments in the field

Unlike traditional wires, fiber optics carry data through light. That means the splice must be precise, clean, and nearly invisible to prevent data loss or signal degradation.

Types of Fiber Splicing

There are two primary methods:

1. Fusion Splicing

This method uses heat (typically from an electric arc) to weld two fiber ends together. It offers:

- The lowest signal loss

- The strongest splice

- Long-term durability in harsh conditions

At TermLink, fusion splicing is the gold standard, especially for high-performance utility and municipal networks.

2. Mechanical Splicing

In this method, fibers are aligned inside a special sleeve or connector without fusing. It’s:

- Faster and easier in the field

- Useful for temporary or emergency repairs

- Not as durable for long-term installations

Mechanical splicing is a helpful tool in specific scenarios but isn’t our go-to for permanent projects.

Why Fiber Splicing Quality Matters

A sloppy splice can mean:

- Data loss or dropped signals

- Weak transmission speeds

- Shortened network lifespan

- Expensive rework or callbacks

That’s why TermLink crews are trained in precise alignment, contamination prevention, and thorough OTDR testing after every splice. We don’t guess, we test and verify every connection.

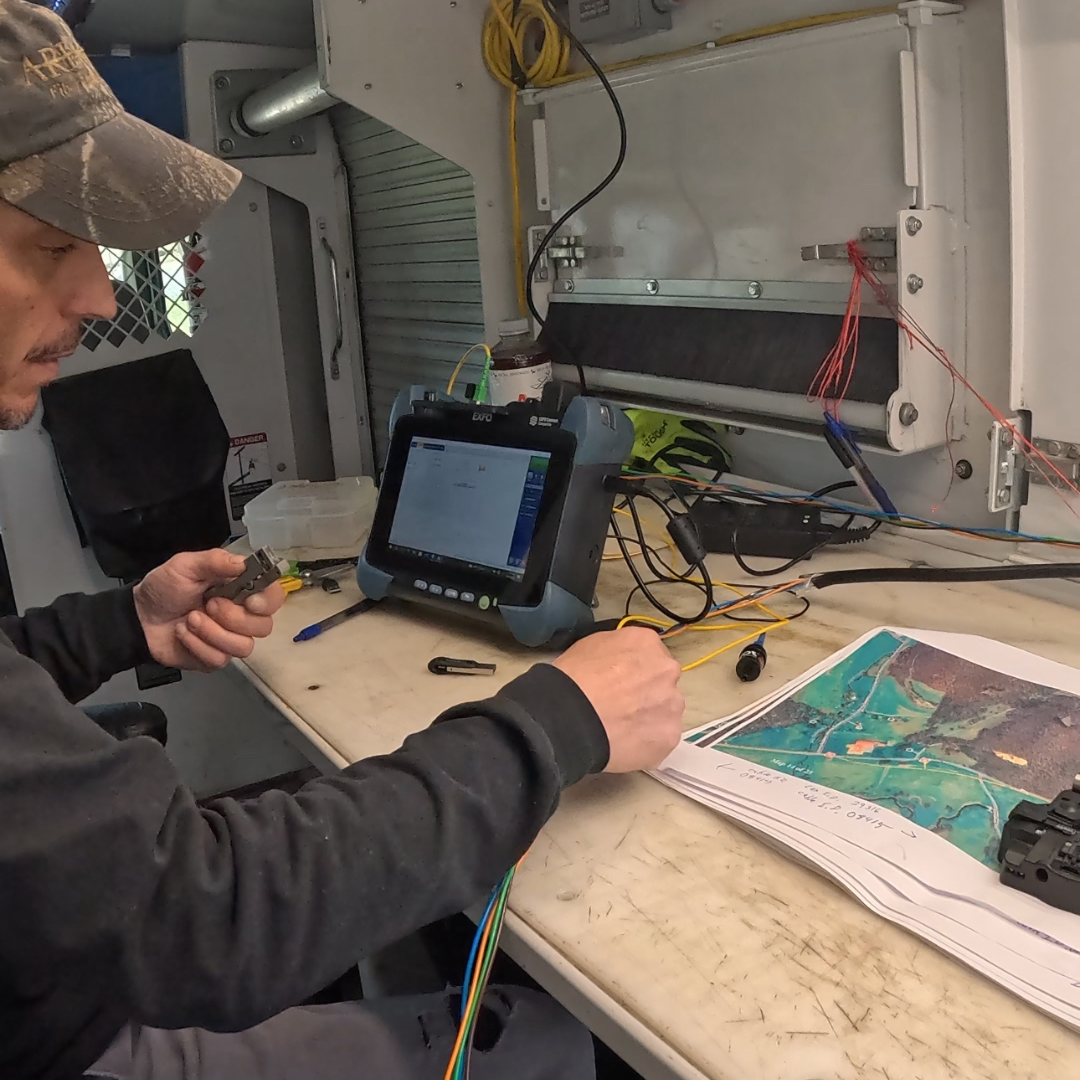

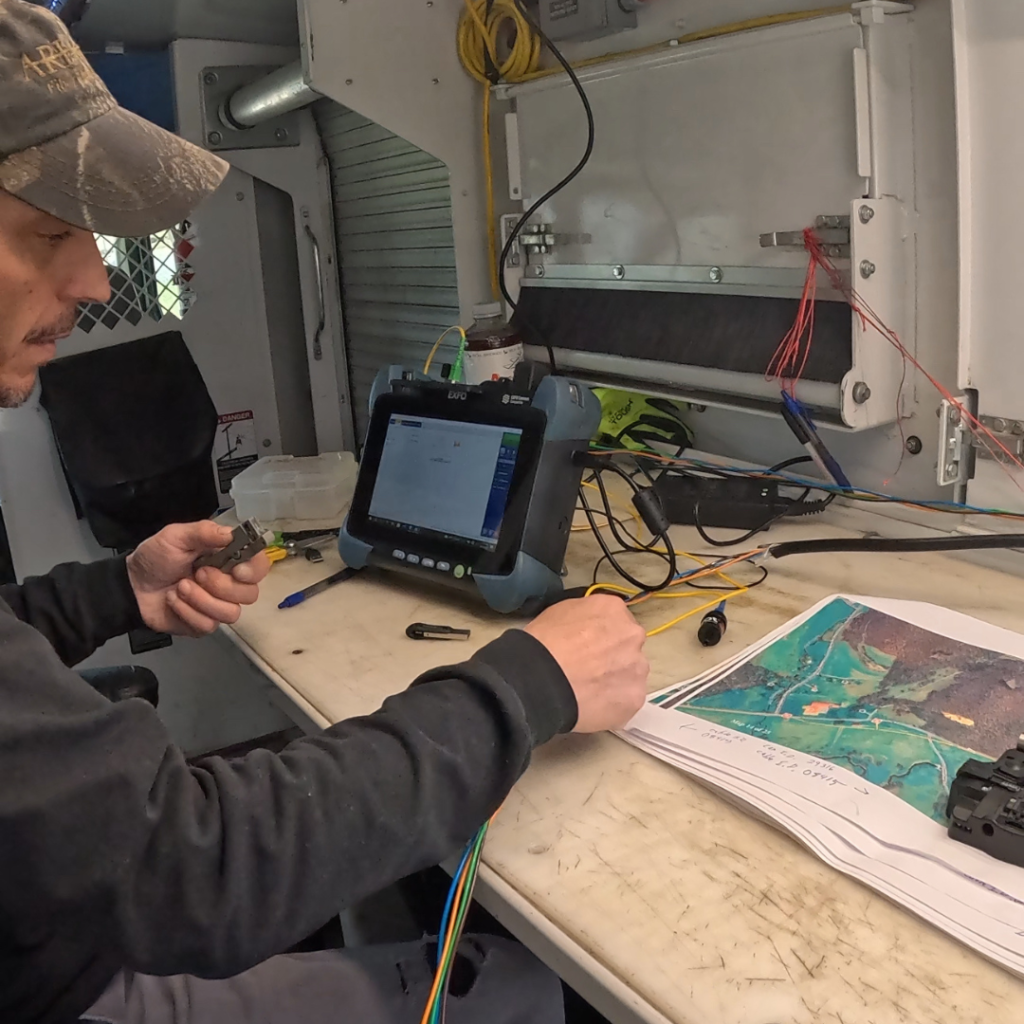

Fiber Splicing in the Field: What It Takes

Splicing in controlled environments like a lab is one thing. Doing it in a bucket truck or roadside splice trailer is another.

Our fiber splicers work with:

- Precision cleavers

- Fusion splice machines

- Splice trays and enclosures

- OTDR and power meters for signal testing

We also maintain climate-controlled trailers to ensure clean environments, even on dusty, wet, or windy job sites.

How We Ensure a Clean, Long-Lasting Splice

TermLink Solutions follows a step-by-step approach:

- Clean and prep the fiber ends

- Cleave the fiber to the correct length and angle

- Align and fuse with a calibrated splicing machine

- Protect and seal with heat shrink sleeves

- Test signal strength using OTDR and light source meters

- Document and log every splice for traceability

It’s this level of detail that protects signal strength—and your investment.

Final Thoughts

Fiber splicing may not be flashy—but it’s the reason your network performs like it should. Whether we’re building a new backbone or repairing existing infrastructure, our team is trained to splice with accuracy, durability, and pride.

If your fiber project demands clean, reliable splicing done right the first time, let’s talk. Contact TermLink Solutions to learn how we deliver connection quality that lasts.