At TermLink Solutions, our crews are the backbone of every fiber installation we deliver. But what does a typical day look like for the people behind the bucket trucks and strand lines?

In this blog, we’re giving you a behind-the-scenes look into a day in the life of a fiber lineman, highlighting the skill, safety, and hustle it takes to power fast, reliable connectivity.

Early Mornings Start with Safety

The day begins early, often before sunrise. Fiber linemen gather at the yard or staging site for a job briefing and safety check, which includes:

- Reviewing site hazards

- Confirming PPE and gear

- Inspecting bucket trucks and equipment

- Outlining the project plan and assignments

Safety isn’t optional, it’s part of the culture. Whether it’s 90° and humid or 20° and icy, linemen prepare for the conditions and communicate constantly to prevent accidents.

Crews follow strict safety protocols aligned with OSHA electrical safety standards to reduce on-site risk.

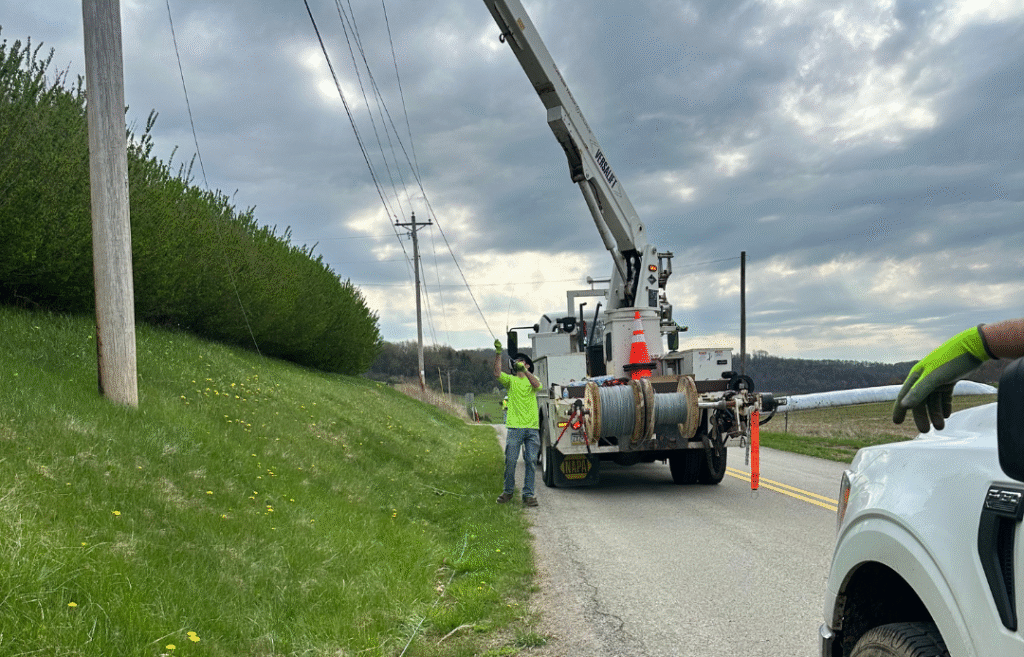

On-Site Setup and Prepping the Pole Line

Once on-site, the crew positions trucks, secures work zones, and prepares strand and fiber for installation. Depending on the project, this could involve:

- Tensioning strand lines

- Pulling aerial cable

- Splicing and sealing fiber connections

- Mounting hardware on utility poles

Being a fiber lineman means working with precision at height, often in unpredictable terrain. The work demands strong spatial awareness, physical endurance, and attention to detail.

Tools of the Trade

No lineman hits the field without their essentials. Some of the everyday tools include:

- Bucket trucks and ladders

- Lasher machines

- Strand jacks and grips

- Fiber splicing kits and OTDR testers

Using the right tool at the right time can mean the difference between a flawless install and a costly mistake. That’s why TermLink linemen are trained extensively before ever climbing a pole.

Problem Solving in Real Time

Even with careful planning, no two job sites are the same. Linemen must think on their feet to solve challenges like:

- Obstructed pole access

- Weather delays

- Unexpected strand tension

- Navigating around existing utilities

Fiber linemen are more than just technicians, they’re problem solvers and field leaders keeping projects moving and clients happy.

Wrapping Up with Accountability

Before calling it a day, linemen:

- Clean up the site

- Verify completion metrics

- Communicate status to project managers

- Log any issues or next steps

Accountability is key. At TermLink, every install is backed by clear documentation and a commitment to quality, safety, and signal integrity.

Why It Matters

Fiber linemen are often unseen by the end user, but without them, the network wouldn’t exist. They’re the boots on the ground making high-speed connectivity possible across cities, suburbs, and rural communities.

If you’ve ever wondered who’s behind the bucket, now you know: it’s TermLink’s skilled, safety-first crews, powering the fiber that powers the future.

Final Thoughts

A day in the life of a fiber lineman is anything but ordinary. It’s fast-paced, hands-on, and critical to the success of every project we take on.

Looking to partner with a team that knows the field, and leads with professionalism? Get in touch with TermLink Solutions to learn more about our services and crews.