When it comes to fiber contractor safety protocols, safety isn’t just a box to check — it’s the foundation of a successful project. Whether the work is happening on a utility pole, in a lift, or alongside live infrastructure, fiber contractors face a unique set of risks every day.

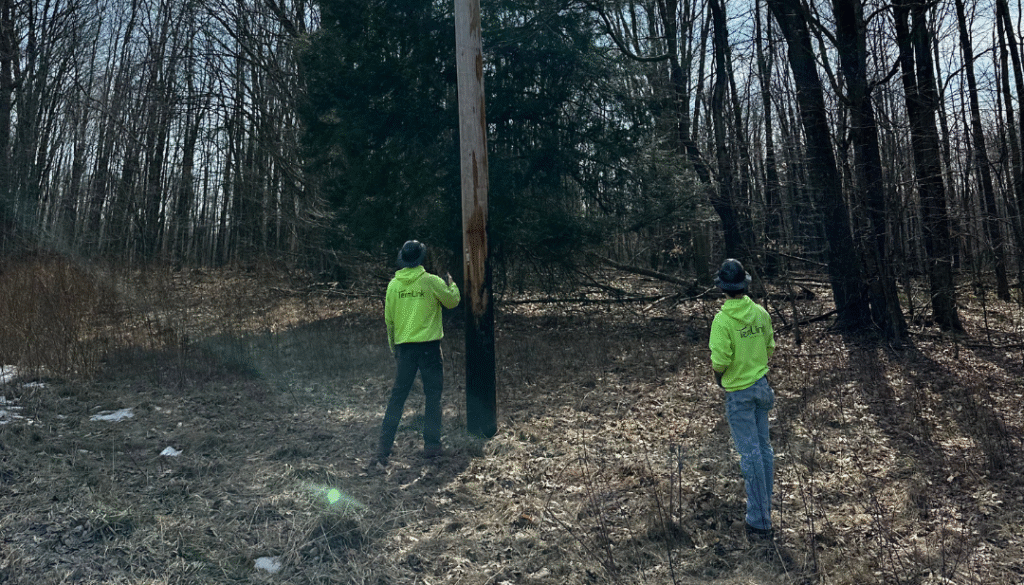

At TermLink Solutions, we prioritize fiber contractor safety on every job site. It’s how we protect our crews, our clients, and the communities we serve. If you’re evaluating fiber partners or looking to strengthen your own safety protocols, here are the five must-haves:

1. Personal Protective Equipment (PPE) Compliance

Before any work begins, PPE is non-negotiable. Proper gear prevents serious injury and ensures compliance with OSHA, ANSI, and client-specific standards.

- High-visibility vests or outerwear

- Hard hats and safety glasses

- Steel-toed boots with non-slip soles

- Gloves rated for cable handling and pole climbing

- Hearing protection and arc-flash gear as needed

At TermLink, all crew members are equipped and trained to use PPE appropriately, and site supervisors enforce usage at all times.

2. Fall Protection for Aerial Work

Aerial fiber installation often involves working at height—on poles, in lifts, or bucket trucks. Falls are one of the leading causes of injury in construction, which makes fall protection absolutely essential.

Every fiber contractor should follow:

- Proper harness use with regular inspection

- 100% tie-off policy when working above 6 feet

- Secure ladder and pole climbing protocols

- Bucket truck operator training and certifications

We implement strict aerial safety policies and ensure our crews are fully trained and certified before working at elevation.

3. Traffic Control and Site Safety

When crews work along roadways or in public spaces, protecting the public is just as important as protecting the team.

Best practices include:

- Using MUTCD-compliant signage, cones, and barriers

- Flaggers and spotters for high-traffic areas

- Clear site boundaries to separate work from passersby

- Vehicle and equipment visibility markers

TermLink follows local and DOT-specific traffic safety regulations to reduce risk during roadside installs and municipal work.

4. Electrical and Pole Safety Awareness

Utility poles often carry more than just fiber. Crews must be trained to recognize the dangers of working near:

- Live electrical lines

- Power transformers

- Overloaded or compromised poles

- Grounding risks and EMF exposure

We always perform a pole assessment before climbing, and follow NESC clearance guidelines to maintain proper distance from power infrastructure. No assumptions—only safe practices.

5. Daily Safety Briefings and Continuous Training

Even with the best equipment, safety culture is what truly prevents accidents. That’s why leading fiber contractors emphasize:

- Daily tailgate meetings to discuss site-specific hazards

- Ongoing training on ladder safety, splicing protocols, and emergency response

- Near-miss reporting to prevent future incidents

- Regular audits and job site inspections

At TermLink, we treat safety as a living system — not a checklist. Every crew member is responsible for maintaining a zero-incident mindset from the first pole to the final splice.

Why It Matters: Safe Installs = Reliable Results

TermLink Solutions delivers aerial fiber installation, splicing, and testing — with safety at the core of everything we do. Our crews are fully trained, properly equipped, and committed to working the right way, every time.

Let’s talk about your next project. Contact us today to schedule a consultation or learn more about our safety-driven approach.